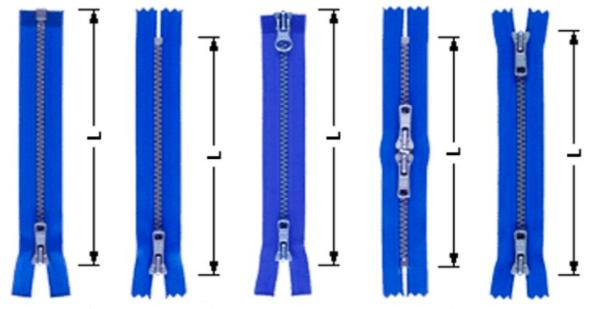

After the length of the zipper is refers to the meshing of the length of the zipper under the natural state of flat, according to actual application. According to different forms of zipper, the zipper length concept is slightly different. Under the different forms of zipper length concept, including open-end zipper, closed-end zipper, double open-end (or called 2-way open-end zipper), double closed-end zipper.

Open-end zipper

The length of the open-end zipper is from the bolt end to the slider, not including the top of the cloth belt.

Closed-end zipper

The length of the closed end zipper is from the stopper to the slider, not including the top and bottom tape.

Double open-end zippers (or called 2-way open-end zipper)

The length of this kind of zipper is from the below slider to the top slider.

Double closed-end zipper

Double closed end zipper can be divided into X and O. They all have two pullers. The length of the closed-end X zipper is from one zipper stopper to another one. The length of the closed end O zipper is from the end of one zipper slider to another slider.

The allowed tolerance

When zippers are in the production process, the mechanical speed, process conditions and chain belt tension, there will be a natural tolerance, and when the longer the length of the zipper, its tolerance are bigger.

The following is the SBS/German/Japanese allowed tolerance

|

Tolerance range of SBS |

|

|

The length of zipper(cm) |

Allowable tolerance |

|

<30 |

±3mm |

|

30-60 |

±4mm |

|

60-100 |

±6mm |

|

>100 |

±1% |

|

The German DIN, 3419 section 2.1 |

|

|

The length of zipper(cm) |

Allowable tolerance |

|

<250 |

±5mm |

|

250-1000 |

±10mm |

|

1000-5000 |

±1% |

|

>5000 |

±50mm |

|

Japanese companies in the new century expo zipper proposed tolerance |

|

|

The length of zipper(cm) |

Allowable tolerance |

|

<30 |

±5mm |

|

30-60 |

±10mm |

|

60-100 |

±15mm |

|

>100 |

±3% |

Post time: Apr-01-2022